THE ANACONDA SR514 RINSING SCREENER HAS BEEN DESIGNED FOR APPLICATIONS THAT REQUIRE THE FIRST STAGE OF PRIMARY WASHING.

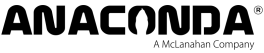

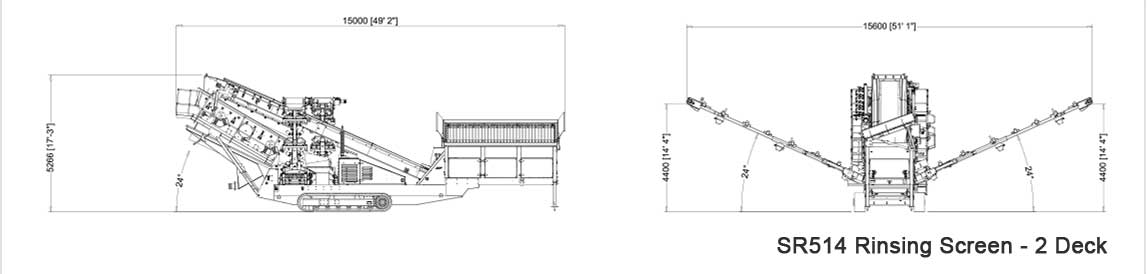

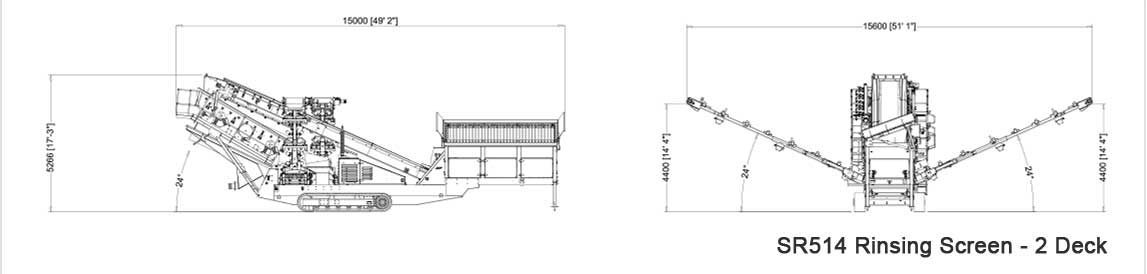

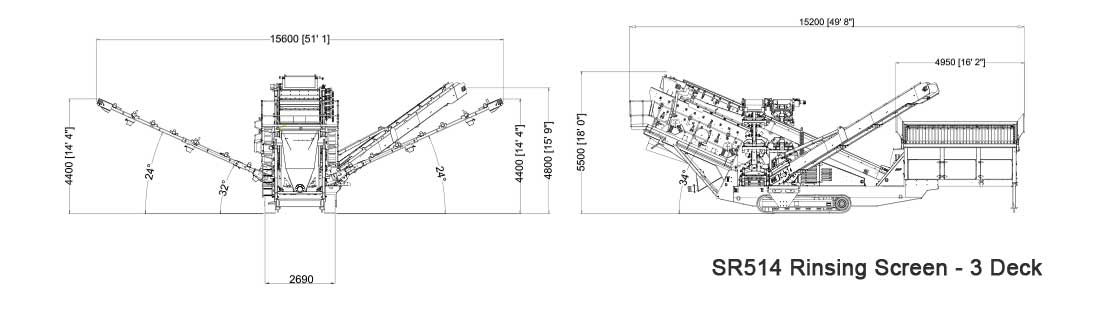

The SR514 Rinsing Screen is powerful and adaptable mobile washing solution. The screen is also very economical to run yet it can still process a capacity of up to 350TPH. Complete with a 14′ x 5′ screen box with the option of 2 or 3 deck, a 14ft feed hopper, main conveyor and either 2 or 3 hydraulically folding stockpiling side conveyors.

The SR514 Rinser is equipt with polymer fan nozzles and a rinser catch box to hold the users end product. This gives the screener the ability to introduce primary washing to a users operation.

This versatile mobile screener is extremely easy to commission and can be tracked around sites for ease of use. The beauty about the SR514 Rinser is it takes into account all aspects of screening with a tipping grid to scalp away the bulky overs, the high energy rinsing screen box for separation of up to four different sizes of end product and also built in conveyors that allow for stockpiling and feeding the machine from the hopper.

FEATURES AND BENEFITS

- TIER 3 – CAT 4.4 OR JCB444 DIESELMAX– ROW

- TIER 4F – JCB444 ECOMAX IPU OR STAGE 5 CAT 3.6 – USA

- STAGE 5 – JCB444 DIESELMAX OR CAT 3.6 – EU

- HIGH ENERGY 4.33M X 1.52M (14’ X 5’) 2 OR 3 DECK RINSING SCREEN

- MAX HOPPER CAPACITY OF 8M³

- SCREEN-BOX ANGLE ADJUSTABLE 22-34º

- HYDRAULIC SCREEN-BOX AND CONVEYORS

- VARIABLE SPEED 4 PLY BELT FEEDER

- VARIABLE SPEED MAIN AND SIDE CONVEYORS

- RADIO REMOTE TIPPING GRID

- POLYMER FAN NOZZLES ON SPRAY BAR (2 DECK X 33 – 3 DECK X 33)

- BRASS NOZZLES ON SPRAY BAR (2 DECK X 41 – 3 DECK X 83 )

- RINSER CATCH BOX

OPTIONS

- SCREEN DECKS – MESH, PIANO WIRE

- 2 OR 3 DECK RINSING SCREEN

- 2 DECK VIBRATING GRID

- RADIO REMOTE CONTROL

- DUST COVERS

- WORKING LIGHTS

- COUPLING FACILITY TO RUN WITH A SCREW WASHER

WEIGHT

- 2 DECK – 26,500 KG

- 2 DECK W/ LIVEHEAD – 31,000 KG

- 3 DECK – 28,500 KG

- 3 DECK W/ LIVEHEAD – 33,000 KG